Surley is a collection of pretreatment and electrophoresis processes Spray booth oven conveying system shower test bench environmental protection technology Accessories workstationstyle all in one store.

OEM Manufacturer Powder Coat Baking Temp - Work station Open Station/Closed Station – Surley

OEM Manufacturer Powder Coat Baking Temp - Work station Open Station/Closed Station – Surley Detail:

Work Station

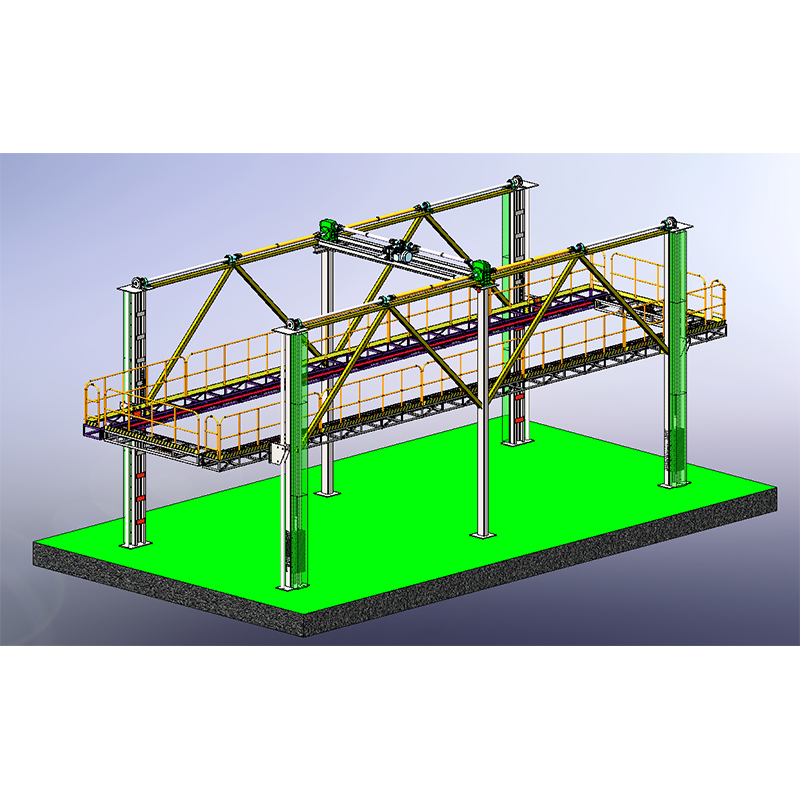

Two types of Station are open station and closed station in terms of the structure.

1、Open type station includes ED inspection, weld sealant, AUDIT, report and submit film, etc.

2、The closed station includes polishing room, PVC spray room, finishing room and small repair room, etc.

Main Functions

There are three main functions in the polishing coating process:

1) remove burrs and sundries on the surface of the substrate (such as floating rust, etc.)

2) to eliminate the roughness and roughness of the particles on the painted surface of the workpiece, such as scraping the surface of the putty after drying the general surface rough and uneven, these problems need to rely on grinding to obtain a smooth surface

3) enhance the adhesion of the coating coating on the smooth surface of the poor adhesion, polishing can enhance the mechanical adhesion of the coating, so polishing is very important.

Product Principle

Polishing waxing polishing

Polishing waxing polishing is to make the finish coating with soft and stable luster, so that the paint surface is more smooth, which is a means to improve the decoration of the coating, generally only in the decorative requirements of high-grade products (high-grade car piano, high-grade furniture, Musical Instruments, etc.) in the coating process In order to achieve the effect of clear paint as a mirror, waxing is also necessary after polishing, and also plays a protective role on the film, so waxing is also a means of maintaining the coating.

Spray paint sealant car paint spray

Spray paint sealant car paint spray (also called acoustic insulation slurry) is the unique process of coating processes of automobile body, only in the body of the sealing glue all welds, under the deck surface (especially round the inner surface buy) with resistance to wear resistant coatings, in order to improve the sealing and corrosion resistance of the body, improve the service life of the car’s comfort and ultimately.

Product Details

Product detail pictures:

Related Product Guide:

We also offer product sourcing and flight consolidation services. We've got our personal factory and sourcing office. We can easily present you with almost every style of merchandise linked to our merchandise range for OEM Manufacturer Powder Coat Baking Temp - Work station Open Station/Closed Station – Surley , The product will supply to all over the world, such as: Amman, El Salvador, United Arab emirates, Our expert engineering team will generally be prepared to serve you for consultation and feedback. We are able to also offer you with free of charge samples to meet your requirements. Best efforts will likely be produced to provide you the best service and merchandise. When you are keen on our business and products, please speak to us by sending us emails or call us quickly. In an effort to know our products and company extra, you may come to our factory to view it. We will generally welcome guests from all over the world to our business to create business relations with us. Please feel cost-free to speak to us for small business and we believe we'll share the best trading experience with all our merchants.

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!