Surley is a collection of pretreatment and electrophoresis processes Spray booth oven conveying system shower test bench environmental protection technology Accessories workstationstyle all in one store.

factory Outlets for Spray Booth Systems - Painting And Powder Coating High Performance – Surley

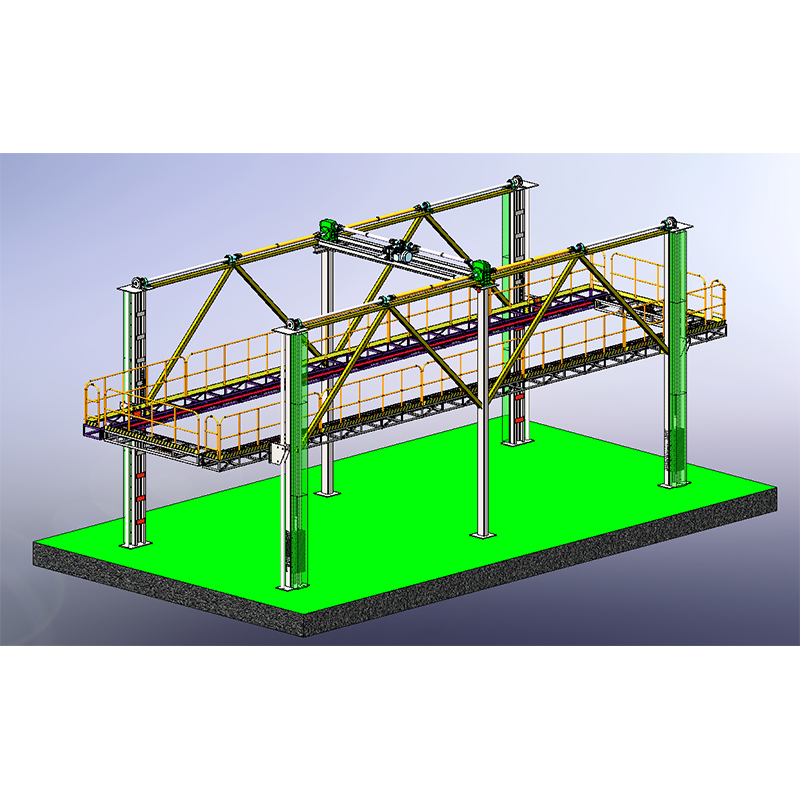

factory Outlets for Spray Booth Systems - Painting And Powder Coating High Performance – Surley Detail:

Product Description

Safe Designs

The spray booth is a special equipment to reduce environmental pollution, provide special coating environment and guarantee coating quality.The basic function of the spray chamber is to collect solvent exhaust gas and scattering paint produced during the coating process, to make the coating exhaust gas and slag be disposed effectively, to reduce the harm to operator and environment, and to avoid effect on the quality of the sprayed workpiece.

Suli’ Industrial Spray Booths are custom designed to satisfy all safety regulations. The protection for all operators in the process of the engineering of your booth is what we care. The protection of the work areas outside of the booth and the environment outside of your facility is also ensured. Overspray can be removed while maintaining a uniform air flow throughout the work area.

Dry filtration technology is applicable for most of spray booth solutions in the industrial manufacturing industry. This is in contrast to water wash booths that can only be justified with very high production rates, as sometimes these high production rates require the use of water wash booths.

Suli’s Powder Coating Booth

In recent years, VOC (Volatile Organic Compounds) emissions have become a focal point of global air pollution. Electrostatic powder spraying is a new type of surface treatment technology with zero VOC emission, energy saving and environmental protection, and will gradually compete with the traditional painting technology on the same stage.

The principle of electrostatic powder spraying is simply that the powder is charged by electrostatic charge and adsorbed to the workpiece.

Compared with traditional painting technology, powder spraying has two advantages: no VOC discharge and no solid waste. Spray paint produces more VOC emissions, and secondly, if the paint does not get on the workpiece and falls to the ground, it becomes solid waste and can no longer be used. The utilization rate of powder spraying can be 95% or more. At the same time, the powder spraying performance is very good, not only can it meet all the requirements of spray paint, but also some indexes are better than spray paint.So, in the future, powder spraying will have a place in order to realize the vision of carbon neutrality at the peak.

Product Details

Product detail pictures:

Related Product Guide:

The really abundant projects management experiences and 1 to just one provider model make the high importance of business enterprise communication and our easy understanding of your expectations for factory Outlets for Spray Booth Systems - Painting And Powder Coating High Performance – Surley , The product will supply to all over the world, such as: Luxembourg, Mexico, Swiss, With good quality, reasonable price and sincere service, we enjoy a good reputation. Products are exported to South America, Australia, Southeast Asia and so on. Warmly welcome customers at home and abroad to cooperate with us for the brilliant future.

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!