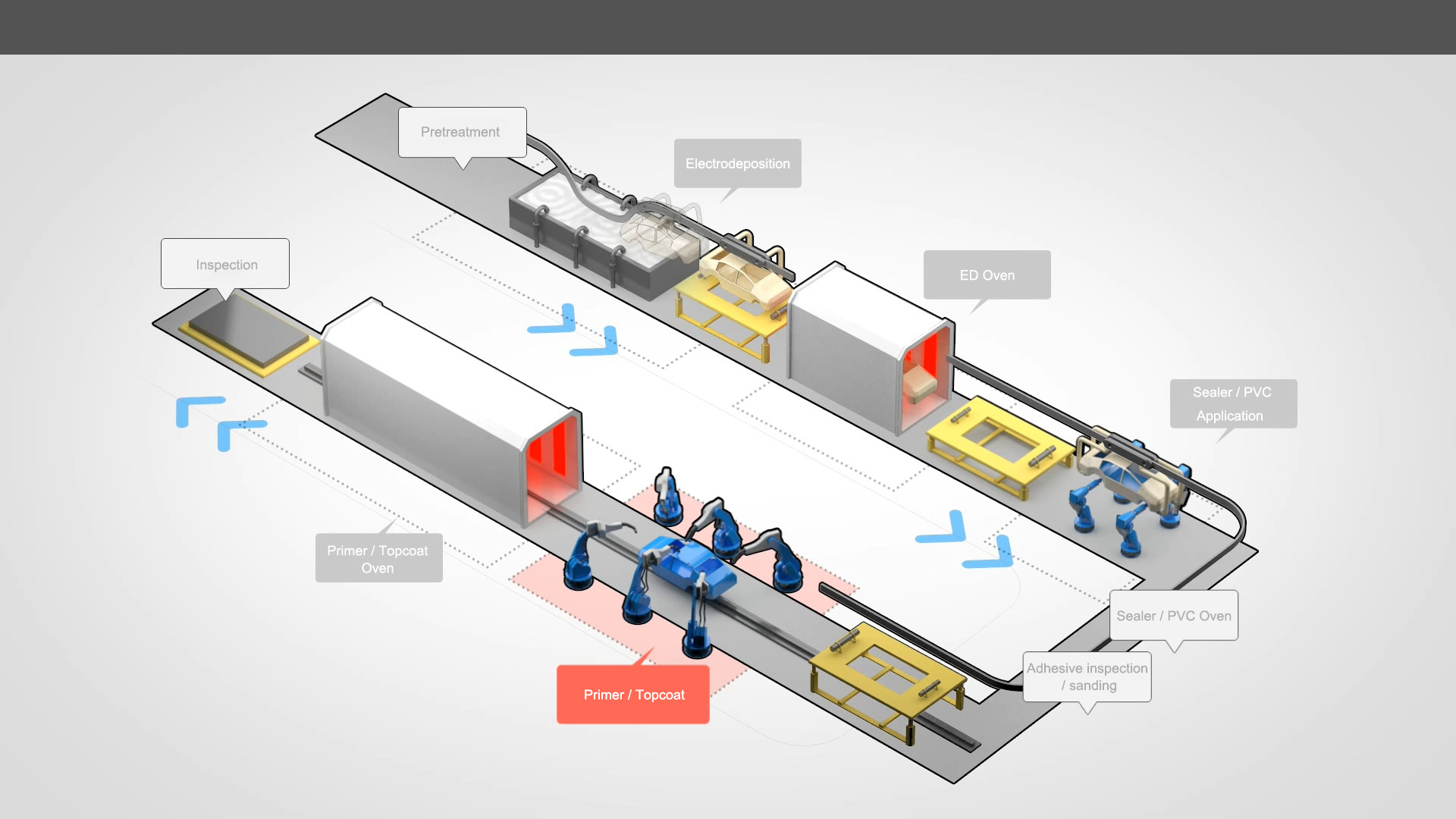

1. Pretreatment: In order to remove unnecessary oil, welding residue, and impurities from the surface of the vehicle body input from the body factory, a zinc phosphate film (3~5㎛) is applied to the body surface to increase adhesion during undercoating (electrodeposition). process. For the purpose of car body corrosion protection.

- Pre-cleaning: After assembling the body, it is washed with water before main degreasing.

- Main degreasing: Removes oil from the car body.

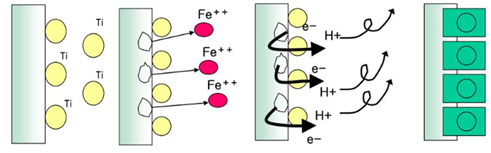

- Rinse conditional: A treatment agent with titanium as the main component, creating a large number of colloids on the metal surface to increase the reactivity for forming a dense zinc phosphate film to produce fine and dense crystals.

- Zinc phosphate film: A zinc phosphate film is applied to strengthen the adhesion of the undercoat and inhibit corrosion reaction.

1) Etching starts at the anode part of the steel sheet in the coating solution

2) Depending on the corrosion current, cations are consumed at the cathode, and the pH of the interface rises.

3) Colloid on the surface becomes a nucleus and crystallizes

- Water dry oven: The process of completely removing moisture from the substrate after the pre-treatment process is completed.

※ Heat transfer and drying in hand drying

After covering the body with a zinc phosphate film ( ), wash it with water and dry it by hand. Hand-cut drying is a process for completely removing moisture from the object to be coated and then performing the next painting process. Raise the temperature to evaporate moisture through heat transfer. Drying (evaporation) is a phenomenon that occurs when the temperature of the solid surface in contact is lower than the boiling point and the atmospheric pressure is lower than the vapor pressure. phase change will occur. The temperature and time required for the hand-cut drying furnace differ depending on the material, thickness, and shape of the object to be coated. Usually, 10 minutes at 120~150℃ is common, and the reason for raising the temperature is to increase the vapor pressure of water corresponding to that temperature and to dry faster by supplying more heat energy. At this time, there should be no metal or chemical change due to temperature.

1、Electrodeposition process: A process of forming a coating film on the inside/outside of a vehicle body by using electrophoresis through electricity after immersing the vehicle body in electrodeposition paint, for the purpose of preventing corrosion of the vehicle body

- Electrodeposition: Electrodeposition painting is a painting process in which the paint is electrically attached by immersing the car body in a paint solution and flowing anode or cathode through the car body. However, it is a method suitable for mass production, and it is difficult to repaint once the coating film is attached and electricity does not flow.

- DI rinse

- Electrodeposition Drying Furnace: For cationic electrodeposition coatings, which are mainly used, a heat-drying furnace is used because the deposited film on the surface is smoothed by thermal fluidization by thermal crosslinking (thermal curing) reaction. The temperature and time required for heat curing vary depending on the material, thickness, and shape of the object to be coated. In the case of a relatively thin coated object, the surface temperature is 200-210°C and the curing furnace temperature is 210-230°C, and the heating time is generally 20-30 minutes in total for 10 minutes or more for the heating time of the object to be coated and 200-210°C holding time.

- Electrodeposition polishing: Grind the rough and protruding parts of the surface to make it smooth.

2、Halfway Paint: This is the process of applying paint, which is often referred to as a primer. It cleans the surface so that the top coat adheres well and plays a role in improving corrosion resistance. I use a slightly different color for the middle to match the color of the top coat.

- Intermediate process

- Medium drying furnace

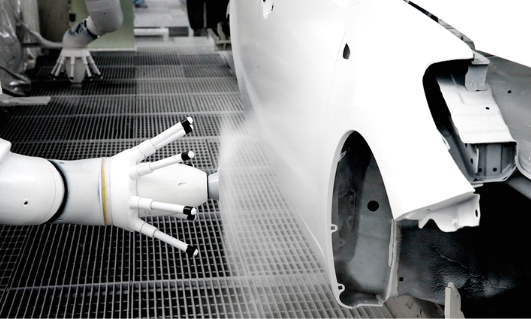

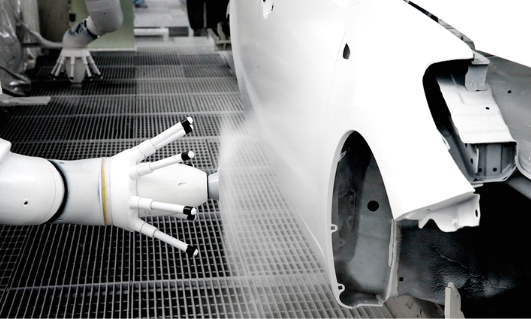

3、top coat: The process of applying the visible vehicle color and finishing with transparent paint. Recently, due to environmental regulations, etc., eco-friendly paints (low volatile substances content) are gradually used. Clear after top coat

- top coat process

- Topcoat drying furnace

※ Heat transfer in electrodeposition/middle/top coat heating and drying furnace

In the drying furnace, heat is transferred to the painted surface in two ways.

Convection: In order to easily reach the thermal curing temperature of the coating film, a fast air flow is required, and high speed convection is obtained by circulating hot air in the drying furnace at a high wind speed (forced convection).

Radiant heat: The wall is heated to several hundred degrees above the curing temperature of the coating film in a specially designed drying furnace, and the heated heat is transmitted to the painted surface in the same way that a stove warms the body.

Post time: Nov-08-2022