Jiangsu Suli Machinery Co., Ltd. has recently successfully delivered the battery pack component coating line project for Tesla’s Berlin factory, marking another major breakthrough for Suli in the international new energy vehicle coating equipment sector. This project covered the entire process from solution design, equipment manufacturing, logistics transportation to on-site installation and commissioning, showcasing Suli’s technical strength and global service capability.

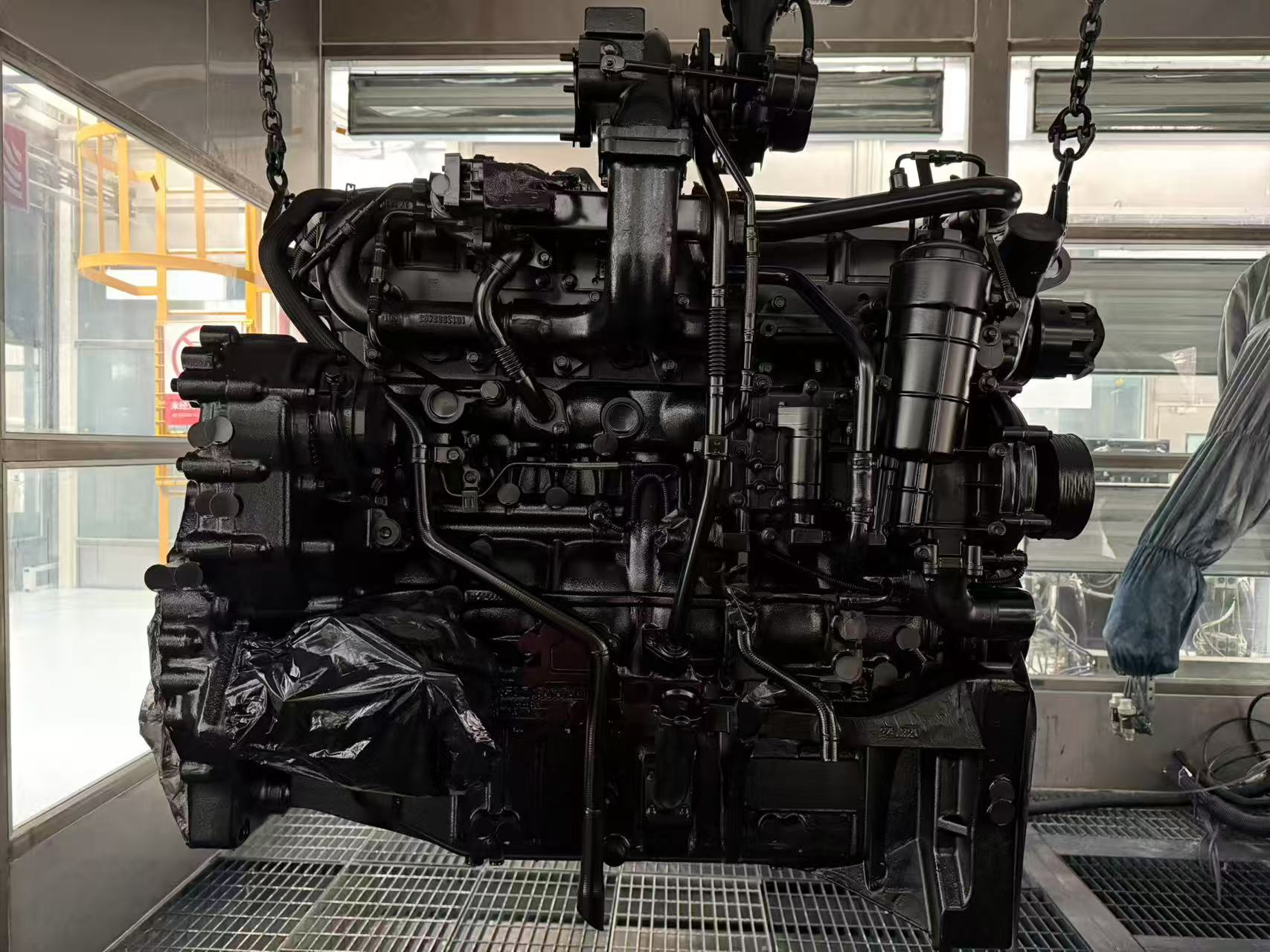

During the project implementation, Suli Machinery innovatively introduced an intelligent spraying scheduling system tailored to Tesla’s stringent requirements for coating quality and efficiency, achieving seamless integration of robotic spraying and manual fine touch-up. This greatly enhanced coating consistency and production flexibility. Combined with a high-performance conveyor system and precise temperature and humidity control equipment, the line ensures optimal coating adhesion and surface quality.

The project employed advanced automated coating equipment alongside strict process controls to achieve efficient, stable, and high-quality coating of battery pack components. The production line design fully considered Tesla’s production rhythm and quality demands, ensuring efficient coordination and precise execution at every stage. Meanwhile, customized coating solutions were developed specifically for the unique materials and process characteristics of battery pack components, effectively improving coating adhesion and corrosion resistance to meet Tesla’s rigorous safety and durability standards.

Facing the complex coordination challenges posed by cross-border construction and commissioning, Suli dispatched an experienced team of engineers to be stationed on-site, fully participating in installation and process debugging, working closely with Tesla’s local technical team to optimize key parameters and ensure on-time smooth project delivery. Remote monitoring systems were also widely utilized to guarantee real-time feedback and adjustment of equipment status and process data.

In terms of environmental protection, the production line adopted advanced exhaust purification technology and energy-saving designs, not only complying with stringent German and EU environmental standards but also effectively reducing operating energy consumption and emission risks. Through integration with a SCADA system, the client can realize intelligent full-process monitoring, improving production transparency and management efficiency.

Since commissioning, Tesla has reported that the production line has significantly enhanced the coating stability and quality consistency of battery pack components, greatly shortened production cycles, and reduced maintenance costs. Jiangsu Suli Machinery will continue to uphold its philosophy of “innovation-driven, quality-first, service-leading,” deepening cooperation with international new energy vehicle giants and promoting continuous progress in green intelligent manufacturing technologies.

Post time: Aug-14-2025