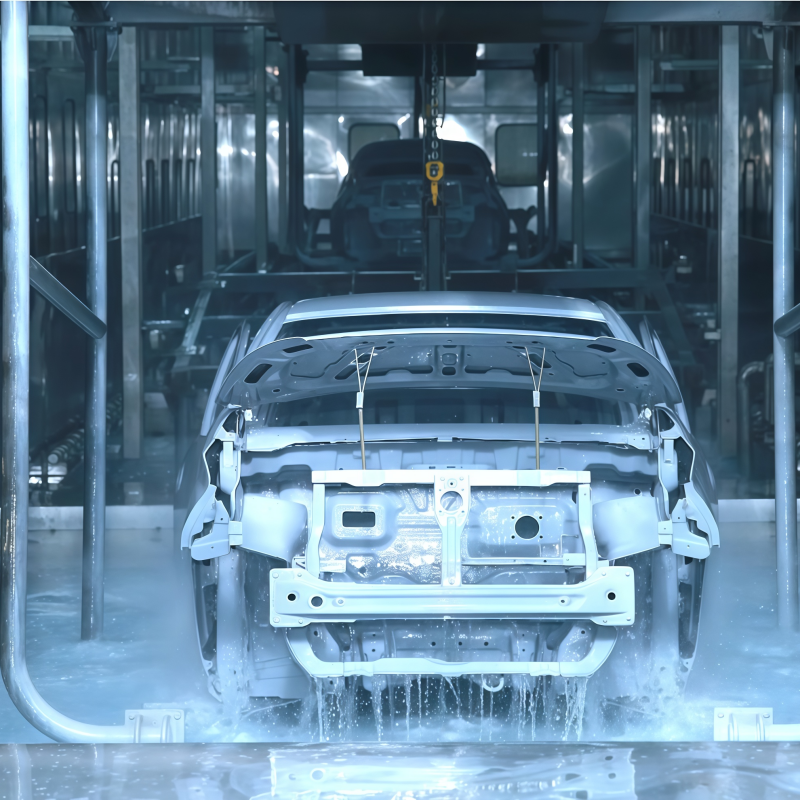

Recently, the Phase II painting production line project undertaken by Jiangsu Suli Machinery Co., Ltd. in India has officially entered the construction stage. The successful commencement of this project marks Suli Machinery’s continued advancement of its localized presence in the Indian market and reflects the company’s steadily growing comprehensive strength and project execution capability in the international painting engineering field.

The Phase II project is an important construction initiative launched on the basis of the successful implementation and stable operation of Phase I. The project covers the construction of a complete painting production line system, involving multi-process integration, multiple systems, and interdisciplinary coordination. Relying on its mature technical system, extensive overseas project experience, and standardized engineering management model, Jiangsu Suli Machinery Co., Ltd. will provide the client with full-process services covering process planning, equipment manufacturing, system integration, on-site installation, commissioning and delivery, as well as long-term operation and maintenance support, ensuring the project is implemented according to schedule and to a high standard.

As a system integrator with more than twenty years of deep engagement in the painting industry, Jiangsu Suli Machinery Co., Ltd. has long focused on technological development and engineering practice in painting production lines, forming a complete, stable, and replicable solution system within the industry. Centered on different product structures and production requirements, the company continues to deliver professional painting production line solutions for passenger vehicles, commercial vehicles, construction machinery, components, and special equipment. To date, Suli Machinery has successfully implemented painting production line projects for more than 1,000 customers, establishing a closed-loop system integration model covering solution design, engineering execution, commissioning and delivery, and long-term operational support.

In terms of industry applications, Suli Machinery’s painting production lines are widely used in passenger vehicle body painting, commercial and special-purpose vehicle painting, complete construction machinery and structural component painting, component powder coating and liquid painting lines, as well as special equipment painting fields with high requirements for surface quality and environmental control. Through extensive domestic and international project practices, the company has continuously accumulated implementation experience under different product types, process routes, and production takt times, enabling it to provide more stable, efficient, and sustainable painting systems for its customers.

Focusing on the core needs of the automotive and component industries, Suli Machinery continues to advance integrated intelligent painting solutions. From early-stage process planning to later-stage operation and maintenance support, the company has formed a complete and closed value service chain. Through five core capability modules—digital process system design, intelligent equipment manufacturing, standardized on-site construction management, full lifecycle commissioning and operation management, and a rapid-response after-sales service system—Suli Machinery delivers turnkey projects that extend from initial project blueprints to customized implementation and final delivery.

In terms of painting production line system configuration, Suli Machinery provides complete sets of equipment and systems covering the entire process flow, including shot blasting equipment; pretreatment and electrophoretic coating systems; powder coating production lines and liquid painting production lines; powder coating systems incorporating robotic automatic spraying equipment and reciprocating spraying equipment; liquid painting equipment; powder rooms; powder supply centers; paint supply systems; mechanized conveying systems; various workstation equipment; automation control and information systems; drying and cooling equipment; curing and forced cooling equipment; air supply systems; as well as supporting wastewater and exhaust gas treatment systems. These solutions comprehensively meet modern painting production requirements for efficiency, quality, safety, and environmental protection.

The official commencement of the Phase II painting production line project in India represents an important milestone in the international development journey of Jiangsu Suli Machinery Co., Ltd. Looking ahead, the company will continue to adhere to technological innovation as its driving force, engineering projects as its foundation, and customer needs as its guide, consistently delivering high-standard and highly reliable painting production line system solutions, expanding its overseas market presence, and creating long-term value for global customers.

Post time: Jan-14-2026