In October 2025, Jiangsu Suli Machinery Co., Ltd. officially made its debut at the Tashkent Industrial Equipment Exhibition in Uzbekistan. From the very first day, Suli’s booth attracted heavy foot traffic, thanks to its proven expertise and numerous successful cases in automated painting lines, welding lines, final assembly lines, and electrophoresis systems.

As a national high-tech enterprise, Suli has long been devoted to the R&D, design, and manufacturing of automated surface treatment and painting systems. At this exhibition, the company showcased its latest range of solutions, including complete vehicle painting lines, plastic component painting and electrophoresis systems, robotic welding cells, and automated assembly lines. These exhibits demonstrated Suli’s comprehensive capability across the entire process chain — from pre-treatment, electrophoresis, painting, drying, and curing to mechanized transport and intelligent control systems.

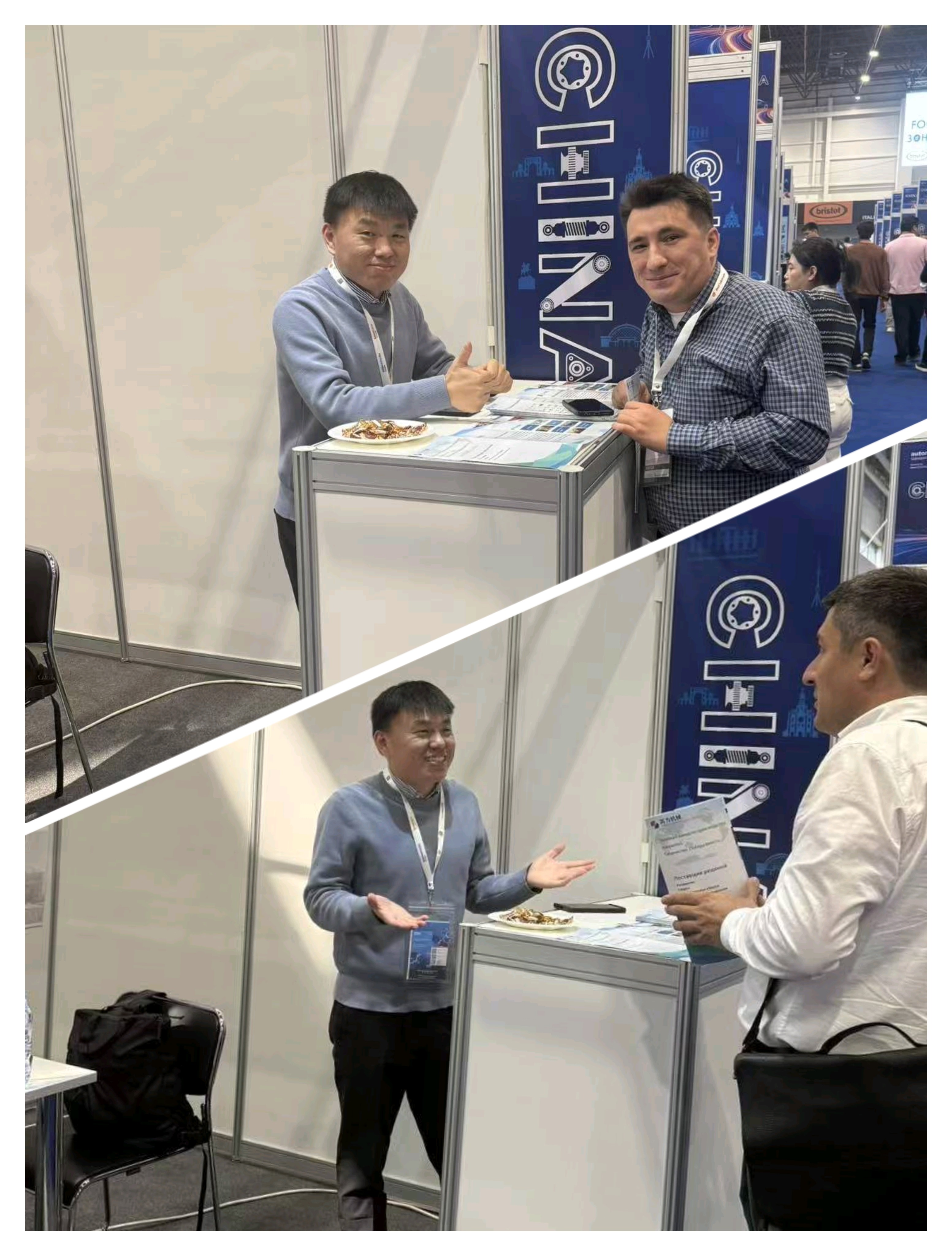

On opening day, Suli’s booth quickly became one of the most visited areas at the show. Visitors from Central Asia, Western Asia, Eastern Europe, Russia, and the Middle East gathered around to learn about Suli’s technical strengths and project portfolio. The booth was designed with a modern, industrial aesthetic — large LED screens displayed videos of completed turnkey projects, while physical equipment models illustrated Suli’s three core technology sectors: automated painting lines, robotic welding units, and assembly line integration systems.

One of the key focuses for visitors was Suli’s electrophoresis coating system, which ensures high-quality corrosion resistance and surface uniformity. Suli’s engineers emphasized how each process stage — degreasing, phosphating, rinsing, activation, and passivation — is precisely controlled and automatically monitored. In the painting stage, robotic spray guns, temperature and humidity control systems, and multi-color change stations ensure coating consistency and energy efficiency. The curing and drying systems feature optimized airflow design, precise temperature distribution, and recovery systems for thermal energy, helping customers achieve both high coating quality and energy savings.

Throughout the first day, Suli’s technical experts interacted closely with customers, explaining how its integrated automation solutions improve efficiency, reduce VOC emissions, and enhance long-term product durability. Visitors expressed admiration for the level of detail in Suli’s project documentation — from layout drawings and process flow diagrams to energy balance charts and maintenance strategies.

Several live technical demonstrations were conducted at the booth: a miniature robotic spray simulation, model electrophoresis tank operations, and film thickness testing using precision instruments. These real-time displays helped visitors understand the complexity and reliability of Suli’s technology.

By the end of the opening day, Suli had already captured the attention of many potential clients seeking long-term partners for turnkey painting and coating solutions. Its professionalism, integrated system design capability, and vast project experience positioned Suli as a trusted partner for industrial manufacturing automation in the Central Asian market.

As the exhibition continues, Suli aims to deepen technical discussions with clients, share insights on automated painting lines, welding automation, assembly system optimization, and explore strategic cooperation opportunities for future projects.

Post time: Oct-22-2025